Plywood is a versatile and widely used building material made from layers of wood veneers bonded together with adhesive. The quality of the bonding between these layers significantly impacts the plywood’s strength, durability, and performance in various applications. Several factors can affect the quality of plywood bonding, including the type of adhesive used, the quality of the wood veneers, the manufacturing process, and environmental conditions. Understanding these factors can help manufacturers produce higher-quality plywood and ensure its effective use in construction, furniture making, and other industries.

1. Type of Adhesive

The adhesive used in plywood production plays a critical role in determining the quality of the bond between the wood veneers. Different adhesives have varying properties, such as strength, water resistance, and temperature tolerance, which can influence the overall performance of the plywood.

- Phenol-Formaldehyde Adhesive: This is a common adhesive used in structural plywood due to its excellent water resistance and strength. It forms a strong, durable bond that can withstand exposure to moisture, making it suitable for exterior and load-bearing applications.

- Urea-Formaldehyde Adhesive: Urea-formaldehyde is often used in non-structural plywood because it provides a strong bond but has lower moisture resistance compared to phenol-formaldehyde. It is suitable for interior applications where the plywood will not be exposed to high humidity or moisture.

- Melamine-Formaldehyde Adhesive: This adhesive offers good water resistance and is often used in decorative plywood, such as for cabinets and furniture. It provides a strong bond and is resistant to abrasion and heat, making it ideal for applications that require durability and a smooth finish.

The choice of adhesive should match the intended use of the plywood, as different adhesives provide different levels of performance under various conditions.

2. Quality of Wood Veneers

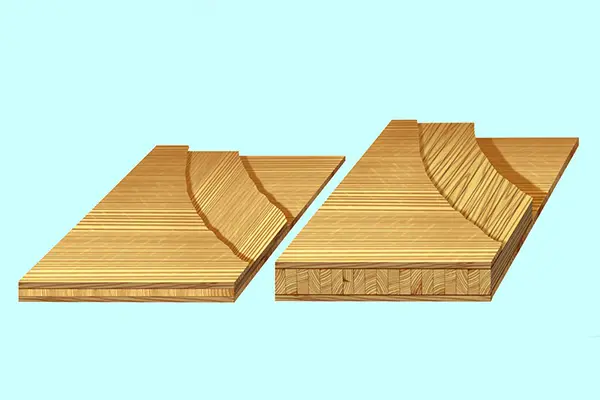

The quality of the wood veneers used in plywood production is another crucial factor affecting the quality of bonding. Veneers are thin slices of wood that are layered and glued together to form plywood. The following aspects of veneer quality can influence bonding:

- Wood Species: Different wood species have varying densities, grain patterns, and moisture content, which can affect how well the adhesive bonds to the wood. Some species, like Douglas fir and pine, are commonly used for plywood due to their favorable bonding properties.

- Veneer Thickness: The uniform thickness of the veneers ensures consistent pressure during the bonding process, which is essential for creating a strong bond. Variations in veneer thickness can lead to weak spots and delamination.

- Moisture Content: The moisture content of the veneers must be carefully controlled during production. If the wood is too wet, the adhesive may not cure properly, leading to weak bonds. Conversely, if the wood is too dry, it can absorb too much adhesive, resulting in an insufficient bond.

- Surface Preparation: The surface quality of the veneers also affects bonding. Smooth, clean surfaces allow for better adhesive penetration and a stronger bond. Rough or dirty surfaces can create gaps and prevent proper adhesion.

3. Manufacturing Process

The plywood manufacturing process involves several steps that can affect the quality of bonding, including adhesive application, pressing, and curing.

- Adhesive Application: The amount and uniformity of adhesive application are critical to ensuring a strong bond. Too much adhesive can lead to excessive squeeze-out and wastage, while too little adhesive can result in weak bonds and gaps between veneers. Modern plywood production uses precise application techniques to ensure the right amount of adhesive is applied evenly.

- Pressing: After the adhesive is applied, the veneers are pressed together under heat and pressure to form the plywood. The pressing process helps the adhesive penetrate the wood fibers and create a strong bond. Inadequate pressure or uneven pressing can lead to poor bonding and delamination. The pressing time and temperature must be carefully controlled to ensure proper adhesive curing and bonding.

- Curing: Curing is the process of allowing the adhesive to set and harden, forming a strong bond between the veneers. The curing process depends on the type of adhesive used and the specific manufacturing conditions. Insufficient curing time or improper temperature control can result in weak bonds and reduced plywood quality.

4. Environmental Conditions

Environmental conditions during and after plywood production can also affect the quality of bonding. Factors such as temperature, humidity, and exposure to chemicals can impact the adhesive’s performance and the durability of the bond.

- Temperature: Extreme temperatures during production or storage can affect the adhesive’s curing process and the overall strength of the bond. High temperatures can cause adhesives to cure too quickly, while low temperatures can prevent proper curing.

- Humidity: High humidity levels can introduce excess moisture into the plywood, affecting both the wood veneers and the adhesive. This can lead to weakened bonds and potential delamination, especially if the plywood is exposed to moisture over time.

- Chemical Exposure: Exposure to chemicals or solvents can degrade adhesives and weaken the bond between the veneers. This is particularly important in environments where plywood may be exposed to harsh chemicals, such as in industrial settings.

Conclusion

The quality of plywood bonding is influenced by various factors, including the type of adhesive used, the quality of the wood veneers, the manufacturing process, and environmental conditions. By carefully selecting the right adhesive, using high-quality veneers, controlling the manufacturing process, and managing environmental conditions, manufacturers can produce plywood with strong, durable bonds that meet the specific needs of different applications. Understanding these factors is essential for ensuring the performance, safety, and longevity of plywood in various construction and industrial projects.

Post time: 08-28-2024