China, one of the world’s largest producers and consumers of wood products, has introduced new GB (Guobiao) standards for Medium Density Fiberboard (MDF) and Laminated Veneer Lumber (LVL). These standards, designed to enhance product quality, environmental sustainability, and safety, are set to have a significant impact on the wood products industry both domestically and internationally. As the industry adapts to these changes, manufacturers, suppliers, and end-users alike will need to understand the implications of these updated regulations.

Overview of MDF and LVL

MDF and LVL are engineered wood products widely used in construction, furniture making, and interior design. MDF is made from wood fibers bonded with resin under heat and pressure, resulting in a dense, smooth panel ideal for cabinetry, moldings, and furniture components. LVL, on the other hand, is created by bonding thin wood veneers together in a parallel arrangement, producing a strong, stable material often used for beams, headers, and other structural applications.

Both products offer advantages over solid wood, such as greater dimensional stability, the ability to use lower-grade wood in manufacturing, and more efficient use of raw materials. However, their production processes also pose challenges, particularly concerning formaldehyde emissions and overall product performance.

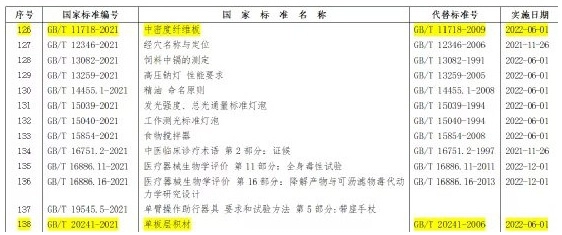

The New GB Standards

The new Chinese GB standards for MDF and LVL, which came into effect this year, are part of an ongoing effort by Chinese authorities to align with international best practices and respond to growing concerns about environmental impact and indoor air quality.

Key Changes in MDF Standards

- Formaldehyde Emission Limits: One of the most significant updates in the new MDF standards is the tightening of formaldehyde emission limits. Formaldehyde, a common component in the adhesives used in MDF production, can release harmful gases over time, posing health risks to consumers. The new standards reduce the allowable formaldehyde emission levels, aligning more closely with international standards such as CARB (California Air Resources Board) and the European E1 standard. This change is expected to drive innovation in low-emission adhesives and promote the use of alternative, eco-friendly bonding agents.

- Physical and Mechanical Properties: The new standards also introduce more stringent requirements for the physical and mechanical properties of MDF. These include criteria for density, internal bond strength, and surface finish. By enhancing these requirements, the standards aim to improve the overall quality and durability of MDF products, ensuring they meet the needs of both domestic and export markets.

- Environmental Sustainability: In line with global trends toward sustainability, the new GB standards emphasize the importance of responsible sourcing and production practices. This includes promoting the use of recycled wood fibers and encouraging manufacturers to adopt sustainable forestry practices. These changes not only help reduce the environmental footprint of MDF production but also support China’s broader environmental goals.

Key Changes in LVL Standards

- Structural Performance: For LVL, the new standards place a greater emphasis on structural performance, with updated criteria for bending strength, modulus of elasticity, and dimensional stability. These changes are particularly important for applications where LVL is used in load-bearing structures, ensuring that the material can withstand the stresses of modern construction.

- Adhesive Quality: Similar to MDF, the new LVL standards also address the quality of adhesives used in production. By setting higher benchmarks for adhesive performance, the standards aim to improve the long-term durability of LVL products, reducing the risk of delamination and failure in structural applications.

- Environmental and Health Considerations: The LVL standards also include stricter controls on formaldehyde emissions and other volatile organic compounds (VOCs), reflecting a broader commitment to improving indoor air quality and reducing the environmental impact of construction materials.

Implications for the Industry

The introduction of these new GB standards is expected to have far-reaching implications for the MDF and LVL industries in China. Manufacturers will need to invest in new technologies and production processes to meet the updated requirements, potentially leading to increased costs in the short term. However, these changes are likely to result in higher-quality products that are safer and more environmentally friendly, ultimately benefiting consumers and the industry as a whole.

For international buyers, the new standards could mean greater confidence in the quality and safety of Chinese wood products, potentially boosting demand in global markets. However, companies that import MDF and LVL from China will need to ensure that their suppliers comply with the new standards to avoid regulatory issues and protect their brand reputation.

Conclusion

The new Chinese GB standards for MDF and LVL represent a significant step forward in improving the quality, safety, and sustainability of wood products. As the industry adjusts to these changes, the emphasis on reducing formaldehyde emissions, enhancing structural performance, and promoting environmental responsibility will likely drive innovation and set new benchmarks for excellence in wood manufacturing. These standards not only reflect China’s commitment to improving product standards but also signal its intention to remain competitive in the global market for engineered wood products.

Post time: 08-21-2024