This article dives deep into the world of MDF (Medium Density Fiberboard) and Melamine Board, two popular materials widely used in furniture, cabinetry, and interior design. We’ll compare their properties, strengths, weaknesses, and ideal applications to help you make an informed decision for your next project. Whether you’re a furniture manufacturer, a cabinet maker, or a DIY enthusiast, understanding the nuances of these materials is crucial for achieving the desired outcome in terms of durability, aesthetics, and cost-effectiveness. This guide will provide valuable insights.

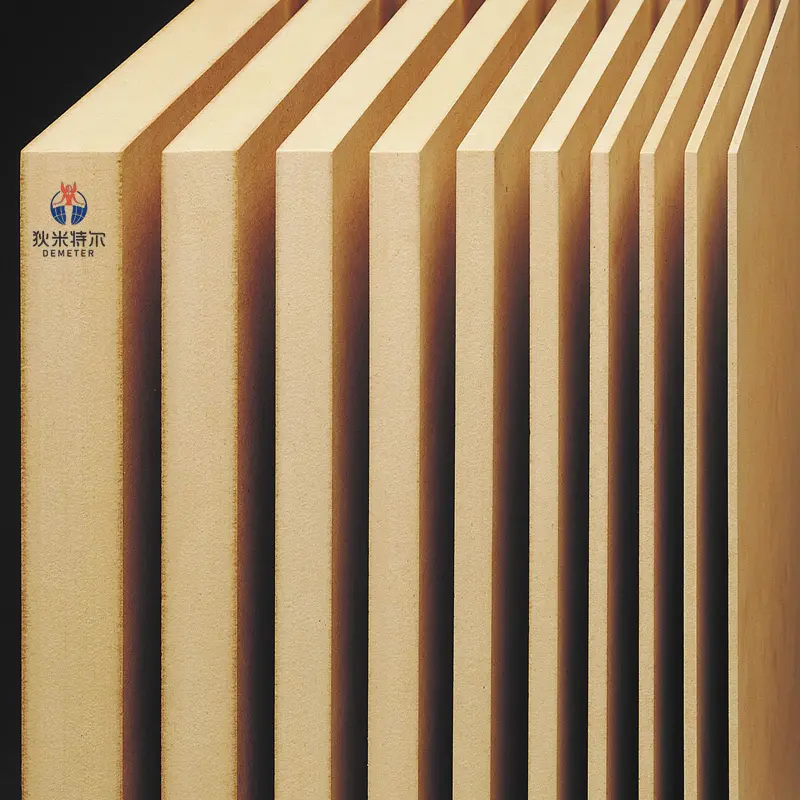

1. What is MDF (Medium Density Fiberboard)?

Medium Density Fiberboard (MDF) is an engineered wood product made from wood fibers. These wood fibers are obtained from breaking down hardwood or softwood residuals. The fibers are then mixed with resin and wax and formed into panels under high pressure and temperature. The result is a dense, stable, and homogenous board with a smooth surface, ideal for various applications.

MDF is commonly used in furniture and cabinetry, shelving, wall panels, and decorative moldings. Because it’s made from wood fibers, it offers a uniform structure, free of knots and voids, that you would typically find in solid wood. The smooth finish of MDF makes it an excellent choice for painting and laminating. MDF promotes tree conservation by utilizing recycled wood fibers, making it a more sustainable alternative to solid wood. However, it’s essential to be aware that some MDF products can emit volatile organic compounds (VOCs) like formaldehyde, raising environmental and health concerns.

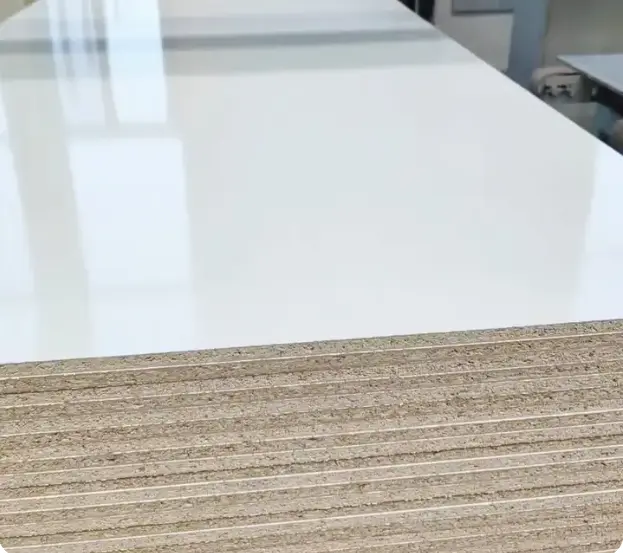

2. What is Melamine Board?

Melamine board is typically a type of engineered wood, like particleboard or MDF, that has a layer of melamine-impregnated paper fused to its surface. Melamine resin is a hard, durable, and scratch-resistant plastic material. This melamine surface provides a decorative and protective coating, available in various colors, patterns, and textures, including wood grain.

Melamine board is widely used in kitchen cabinets, furniture, shelving, and other interior applications. The melamine provides a waterproof and easy-to-clean surface, making it suitable for high-traffic areas like kitchens and bathrooms. It’s also a more affordable option compared to solid wood or veneer. Melamine is a protective coating that significantly enhances the board’s durability. It makes MDF or particle board surface to which it is applied, more resistant to scratches, moisture, and stains.

3. MDF vs. Melamine Board: A Direct Comparison

| Feature | MDF | Melamine Board |

|---|---|---|

| Composition | Wood fibers, resin, wax | Particleboard or MDF core, melamine layer |

| Surface | Smooth, unfinished | Smooth, finished, various colors/patterns |

| Durability | Moderate, susceptible to water damage | High, scratch and water-resistant |

| Cost | Generally less expensive | Slightly more expensive than raw MDF |

| Applications | Painting, laminating, general use | Kitchens, bathrooms, high-use areas |

| Water Resistance | Low | High |

| Scratch Resistance | Medium | High, Scratch-resistant than MDF |

| Weight | Heavier than plywood | Depends on the core material |

While MDF provides a versatile base, melamine board offers enhanced durability and a finished look. The decision between melamine and MDF ultimately hinges on the specific project requirements. For instance, if you’re building painted bookshelves, MDF might be sufficient. However, for kitchen cabinets, the water resistance and scratch-resistant surface of melamine make it a preferred choice.

4. How Does the Manufacturing Process Differ Between MDF and Melamine?

The production process for MDF involves breaking down wood particles into fibers, mixing them with resin and wax, and then pressing them into panels under high pressure and temperature. This creates a dense, uniform board.

Melamine board, on the other hand, starts with a core material, which can be particleboard or MDF. The manufacturing process then involves applying a layer of melamine-impregnated paper to one or both sides of the core board. This layer is fused to the core using heat and pressure, creating a permanent bond.

5. Is Melamine Board More Durable Than MDF?

Yes, melamine board is generally more durable than raw MDF. The melamine layer provides a hard, scratch-resistant, and waterproof surface, making it better equipped to withstand daily wear and tear. MDF, in its raw form, is more susceptible to moisture damage and can warp or swell if exposed to water.

The enhanced durability of melamine makes it an excellent choice for furniture and cabinetry in high-traffic areas or environments prone to moisture, such as kitchens and bathrooms. Although MDF is also engineered for stability, making it less prone to warping than solid wood, it doesn’t offer the same level of protection against liquids as melamine.

6. What are the Cost Differences Between MDF and Melamine?

MDF is generally less expensive than melamine board. This is because melamine board involves an additional step in the manufacturing process – the application and fusing of the melamine layer. However, while raw MDF might be cheaper initially, consider the additional costs of finishing it with paint or another sealant.

Melamine board, while slightly pricier, offers a finished product that requires no further surface treatment. Therefore, the overall cost difference might be negligible depending on your project’s finishing requirements. For a buyer like Mark Thompson, who is quality-sensitive but also seeks competitive pricing, understanding this cost-benefit analysis is crucial.

7. Which is Better for Kitchen Cabinets: MDF or Melamine?

For kitchen cabinets, melamine board is often the preferred choice. The kitchen is a high-moisture environment, and the water-resistant properties of melamine offer significant advantages. Spills and splashes are easily wiped clean, and the material is less likely to warp or swell compared to MDF.

MDF can be used for kitchen cabinets, but it requires thorough sealing to protect it from moisture. Melamine’s inherent durability and resistance to scratches also make it a better choice for withstanding the daily wear and tear of a busy kitchen. For professional cabinet makers and furniture manufacturers, melamine offers both aesthetic appeal and long-term performance.

8. Can I Paint MDF and Melamine Board?

Yes, you can paint both MDF and melamine board, but the process and results differ. MDF, with its smooth surface, is very receptive to paint. It provides an excellent base for a smooth, even finish. However, it’s crucial to properly prime the MDF before painting, especially the edges, to seal it and prevent moisture absorption.

Melamine board, while already having a finished surface, can also be painted. However, it requires specific preparation. The smooth, non-porous melamine surface needs to be lightly sanded and primed with a bonding primer designed for laminate surfaces. This ensures proper paint adhesion. Painting melamine is often done to change the color or add a custom finish, rather than for protection, as the melamine layer already provides that.

9. What are the Environmental and Health Considerations of MDF and Melamine?

Both MDF and melamine board have environmental and health considerations, primarily related to formaldehyde emissions. Formaldehyde is a volatile organic compound (VOC) used in the resins that bind the wood fibers in MDF and can be present in the melamine resin itself.

Exposure to high levels of formaldehyde can cause irritation and other health problems. However, many manufacturers now produce MDF and melamine board that comply with stringent emission standards, such as CARB P2 (California Air Resources Board Phase 2) and E1/E0 (European standards). When sourcing these materials, it’s essential to check for certifications that guarantee low formaldehyde emissions. Allen, from Demeter, emphasizes that their products meet these standards, ensuring a safer product for customers like Mark. DEMETER Melamine MDF board panel 3mm 6mm 10mm 15mm 16mm 17mm 18mm manufacturer wood MDF for furniture cabinet wardrobe is good example.

10. Where Can I Source High-Quality MDF and Melamine Board?

Finding a reliable supplier is crucial for ensuring the quality and consistency of your materials. Companies like Demeter in China specialize in manufacturing high-quality wood-based panel products, including RAW MDF, melamine faced board, and decorative papers. They export to key markets like the USA, North America, Europe, and Australia.

For procurement officers like Mark Thompson, attending exhibitions is a great way to connect with potential suppliers like Demeter. These events allow for face-to-face interactions, quality inspections, and discussions about specific requirements. Online platforms and Google search are also effective ways to find suppliers. When evaluating suppliers, key considerations include:

- Certifications: Look for certifications like CARB P2, E1/E0, and FSC (Forest Stewardship Council) to ensure product quality and sustainability.

- Quality Control: Inquire about the supplier’s quality control processes to ensure consistent product quality, including surface finish, core quality of MDF, color consistency, and print accuracy.

- Logistics and Payment: Discuss shipping arrangements, lead times, and payment methods to ensure a smooth transaction.

- Moisture content and dimensional accuracy: Essential items, especially for MDF and Melamine boards intended for furniture or cabinetry.

- Communication: Check, if communication is fluent. This will prevent potential misunderstandings.

Demeter, for example, offers a wide range of melamine paper designs and colors, along with different thicknesses and sizes of MDF and melamine board. They also provide edge banding materials to complete your project. This kind of one-stop-shop approach can be very beneficial for buyers looking for comprehensive solutions.

Here is another example of product manufactured by Demeter:

And some Factory export melamine LSB

Summary: Key Takeaways

- MDF is an engineered wood product made from wood fibers, resin, and wax, offering a smooth and uniform surface.

- Melamine board is a composite material with a particleboard or MDF core and a decorative, durable melamine surface.

- Melamine board is generally more durable, water-resistant, and scratch-resistant than raw MDF.

- MDF is typically less expensive than melamine board, but finishing costs should be considered.

- Melamine board is often the preferred choice for kitchen cabinets due to its moisture resistance.

- Both MDF and melamine board can be painted, but melamine requires specific preparation for optimal results.

- Formaldehyde emissions are a consideration for both materials; look for certifications indicating low emissions.

- Reliable suppliers, like Demeter, provide high-quality MDF and melamine board, catering to various needs.

- Attending exhibitions and using online platforms are effective ways to find and evaluate suppliers.

- When sourcing, prioritize certifications, quality control, logistics, and clear communication.

Post time: 03-25-2025