In the realm of woodworking and construction, materials play a crucial role in determining the durability, aesthetics, and functionality of a project. Among these materials, chipboard and plywood are two popular choices often used in furniture making, cabinetry, and various construction applications. However, many people may wonder whether chipboard is a type of plywood or if they are distinct materials altogether. This article aims to clarify the differences between chipboard and plywood, their manufacturing processes, and their respective uses.

What is Chipboard?

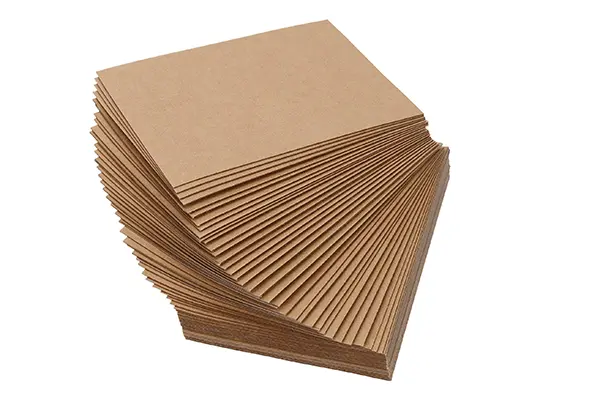

Chipboard, also known as particle board, is an engineered wood product made from wood chips, sawmill shavings, or even sawdust. These materials are combined with adhesive resins and compressed under high pressure to form dense sheets. The manufacturing process of chipboard typically involves several steps:

- Material Preparation: Wood chips or particles are collected and sorted.

- Mixing with Adhesives: The wood particles are mixed with adhesives that help bind them together.

- Pressing: The mixture is placed in a hydraulic press, where heat and pressure create solid sheets.

- Finishing: The sheets are cut to size, sanded, and may be finished with laminates or veneers for a more attractive appearance.

Chipboard is known for its affordability and versatility, making it a popular choice for budget-conscious projects.

What is Plywood?

Plywood, on the other hand, is also an engineered wood product but is constructed using thin layers or “plies” of wood veneer. Each layer is glued together with the grain of adjacent layers running in opposite directions, which provides strength and stability. The manufacturing process of plywood includes:

- Veneer Production: Logs are peeled or sliced into thin sheets of veneer.

- Layering: The veneers are layered with adhesive, ensuring that the grains of adjacent layers are perpendicular.

- Pressing: The layered veneers are pressed together under heat and pressure to bond them into a single sheet.

- Finishing: The plywood sheets are cut, sanded, and can be finished or laminated for added aesthetics.

Plywood is renowned for its strength, durability, and resistance to warping, making it suitable for a wide range of applications, including structural uses.

Key Differences Between Chipboard and Plywood

- Composition: The most significant difference lies in their composition. Chipboard is made from wood particles, while plywood is constructed from thin layers of veneer. This fundamental difference affects their structural properties and performance.

- Strength and Durability: Plywood is generally stronger and more durable than chipboard. The cross-laminated structure of plywood provides better resistance to bending and warping, making it ideal for load-bearing applications. Chipboard, while adequate for many uses, is more susceptible to damage from moisture and may not withstand heavy loads.

- Weight: Chipboard is usually heavier than plywood of the same thickness due to its dense composition. This weight can be a consideration when selecting materials for certain applications.

- Cost: Chipboard is typically less expensive than plywood, making it a popular choice for budget-friendly projects like basic furniture, shelving, and cabinetry where high strength is not a primary concern.

- Surface Finish: Plywood often has a more attractive surface finish due to the natural grain of the wood veneer, making it suitable for visible applications like furniture and cabinetry. Chipboard, on the other hand, is often covered with a laminate or veneer to improve its appearance, as the raw surface is not aesthetically pleasing.

Applications of Chipboard and Plywood

- Chipboard: Commonly used for furniture, cabinetry, and interior applications where strength is less critical. It is often found in lower-cost furniture and as a substrate for laminate surfaces.

- Plywood: Widely used in construction, flooring, furniture making, and cabinetry, particularly in applications where strength and durability are essential, such as roofing and wall sheathing.

Conclusion

In summary, chipboard and plywood are distinct engineered wood products with different manufacturing processes, compositions, and applications. While chipboard is made from wood particles and is often more affordable, plywood is constructed from layers of veneer, offering greater strength and durability. Understanding these differences is crucial for making informed decisions when selecting materials for woodworking or construction projects. Each has its advantages, and the choice between them will depend on the specific requirements of your project.

Post time: 11-01-2024