Particle board is a common, affordable material used in furniture, cabinetry, and flooring. While it’s widely favored for its low cost and ease of use, particle board is also more prone to damage compared to solid wood or plywood. It can chip, crack, swell from water damage, or break under heavy weight. However, with the right techniques and tools, you can repair particle boards and extend the life of your furniture or other household items. This guide will walk you through several methods for fixing different types of damage to particle boards.

1. Assess the Type of Damage

Before you start the repair process, it’s essential to identify the type and extent of the damage to your particle board. Common issues include:

- Chips or cracks: Small chips or cracks in particle boards often occur at edges or corners.

- Swelling or water damage: Water exposure causes particle boards to swell or become soft and crumbly. This is a more severe issue that may require replacing sections of the material.

- Broken sections: If a piece of particle board has snapped or a corner has broken off, you may need to rebuild or replace that area.

Once you know what type of damage you’re dealing with, you can select the most appropriate repair method.

2. Tools and Materials You’ll Need

To repair particle board, you’ll need a few essential tools and materials, depending on the type of damage:

- Wood filler or epoxy putty

- Sandpaper (medium to fine grit)

- Utility knife or chisel

- Wood glue

- Clamps (for larger repairs)

- Primer and paint (if repainting is necessary)

- Plastic spreader or putty knife

3. Repairing Small Chips and Cracks

If your particle board has small chips, cracks, or minor surface damage, you can repair it with wood filler or epoxy putty. Here’s how:

- Clean the Area: Start by cleaning the damaged area to remove any loose debris, dirt, or dust. You can use a soft brush or cloth to clean the surface.

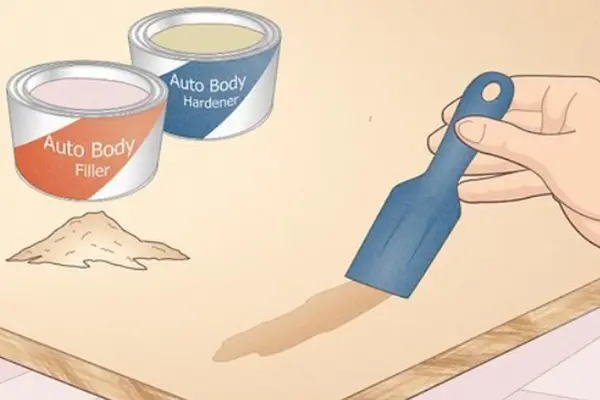

- Apply Wood Filler: Use a wood filler or epoxy putty to fill in the crack or chipped area. Scoop a small amount of filler onto a plastic spreader or putty knife and press it into the damaged section. Be sure to slightly overfill the crack so you can sand it down for a smooth finish later.

- Allow to Dry: Let the filler or putty dry completely, following the manufacturer’s instructions. Most wood fillers take several hours to cure fully.

- Sand the Surface: Once the filler has dried, sand the repaired area with medium to fine-grained sandpaper. Sand until the surface is smooth and level with the surrounding particle board.

- Prime and Paint: If the particle board was originally painted or finished, you may need to prime and paint the repaired area to match. Use a primer suitable for particle board, followed by your chosen paint or finish.

4. Fixing Swollen or Water-Damaged Particle Board

Water damage is one of the most common issues with particle boards, especially in areas like kitchens and bathrooms. Water causes the board to swell, weaken, and crumble. In cases of severe water damage, replacing the damaged section is often the best solution. However, for minor swelling, here’s what you can do:

- Dry the Area: If the particle board is still wet, allow it to dry completely before attempting any repairs. You can use a fan or hairdryer to speed up the process. Make sure the board is thoroughly dry before proceeding.

- Sand the Swollen Area: Use sandpaper or a power sander to sand down the swollen, raised area of the particle board. Sanding will help level the surface and remove any damaged particles.

- Apply Wood Filler: If the sanding process leaves behind any gaps or holes, fill them with wood filler or epoxy putty. Spread the filler over the area with a putty knife and smooth it out.

- Sand Again and Finish: Once the filler dries, sand the area again to achieve a smooth surface. If necessary, apply a primer and repaint the particle board to match its original finish.

5. Repairing Broken Sections of Particle Board

If a corner or section of the particle board has broken off completely, you’ll need to repair it using wood glue or an adhesive for the particle board.

- Clean the Area: Remove any loose debris or crumbled material from the broken section. Use a chisel or utility knife to clean up the edges of the break.

- Apply Wood Glue: If the broken piece is still intact, apply wood glue to both the broken edge and the corresponding piece of the particle board. Press the two pieces together and secure them with clamps. Leave the clamps in place until the glue has fully dried, which typically takes 24 hours.

- Rebuild with Epoxy Putty: If the broken section is missing, you can rebuild it using epoxy putty. Mix the putty according to the package directions, then mold it to fill the gap or recreate the missing section. Once the putty hardens, sand it smooth.

- Finishing Touches: After repairing the broken section, sand the area to ensure it’s smooth. Prime and paint the particle board if needed.

6. Preventing Future Damage

To prevent future damage to particle board, it’s important to protect it from moisture and excessive weight:

- Seal the Edges: Particle board edges are particularly vulnerable to moisture. Sealing them with paint, varnish, or edge banding can help protect the board from water damage.

- Avoid Excessive Weight: The particle board is not as strong as solid wood or plywood, so avoid placing heavy items on unsupported surfaces.

- Keep Dry: Always keep particle board furniture or flooring away from water or high-humidity environments, especially if it hasn’t been sealed properly.

Conclusion

Repairing particle boards is a relatively straightforward process that can help you extend the life of your furniture, cabinets, or other particle board items. By using the right tools, materials, and techniques, you can fix chips, cracks, water damage, and broken sections, restoring the functionality and appearance of your particle board. With proper care and attention, your repaired particle board can last for years to come.

Post time: 10-17-2024