This article delves into the world of Medium Density Fiberboard (MDF), focusing specifically on the versatile 8mm MDF board and its impact on interior design and furniture manufacturing. We’ll explore why this particular thickness offers a sweet spot between strength, workability, and price, making it a popular choice for a wide range of applications. Whether you’re a professional furniture maker or a DIY enthusiast, understanding the benefits of 8mm MDF will help you select the right material for your next project. Let me, Allen, from a leading Chinese MDF factory, guide you through this.

What Exactly is MDF, and Why Should You Care?

Medium-density fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. The result is a dense, flat, and stiff sheet with a smooth surface that’s ideal for various applications, especially in furniture making and interior design.

Why should you care? Because MDF offers several advantages over solid wood or plywood. It’s more economical, has a consistent density throughout (no knots or voids), and provides a superior surface for painting, laminating, and veneering. Here at Demeter, we produce MDF that holds screws well and is less prone to warping or splitting than solid wood. This product is a true value for any cabinet maker.

What Makes 8mm MDF Board Stand Out from Other Thicknesses?

While MDF board comes in a range of thicknesses, from thinner 3mm sheets to thicker 25mm panels, the 8mm (8mm thickness) variant offers a unique balance of properties. It’s substantial enough to provide good structural integrity for many applications, yet it’s still relatively lightweight and easy to handle.

Compared to thinner options like 4mm or 6mm MDF, 8mm MDF provides greater rigidity and is less prone to bending or flexing. Compared to thicker boards (12mm, 15mm, 18mm), it’s more affordable and easier to cut and shape, reducing material waste and machining time. This makes it ideal for projects where a balance of strength, workability, and cost-effectiveness is crucial. This thickness of MDF is perfect for making drawers in your furniture.

Is 8mm MDF Strong Enough for My Furniture Project?

The strength of 8mm MDF is sufficient for a surprising number of furniture applications. While it might not be suitable for load-bearing elements in large, heavy structures, it excels in:

- Cabinet backs and sides.

- Drawer bottoms.

- Shelving units (with appropriate support).

- Decorative panels.

- Door skins.

- Light-duty tabletops.

- Interior decoration.

The key is to consider the specific load requirements of your project. For instance, if you’re building shelves that will hold heavy books, you might need to reinforce the 8mm MDF with additional supports or choose a thicker board. However, for most typical furniture components, 8mm MDF provides ample strength and stability.

How Does the Price of 8mm MDF Board Compare to Other Options?

The price of MDF board generally increases with thickness. Therefore, 8mm MDF board price is typically lower than that of thicker boards (like 12mm or 18mm) and higher than thinner boards (like 3mm or 6mm). The actual price will also vary depending on factors like:

- Grade of the MDF (e.g., standard, moisture-resistant, fire-retardant).

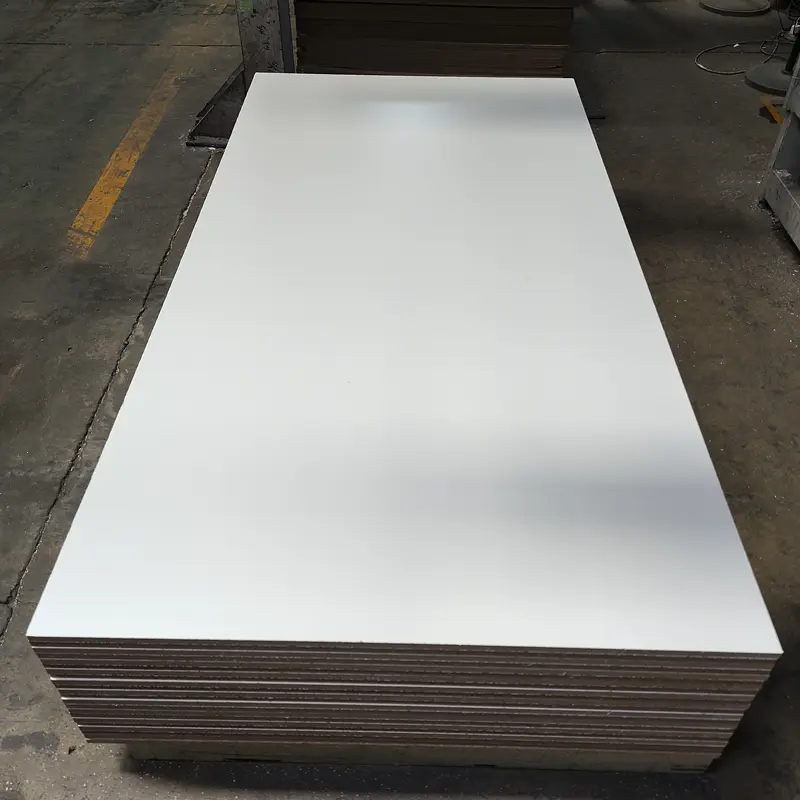

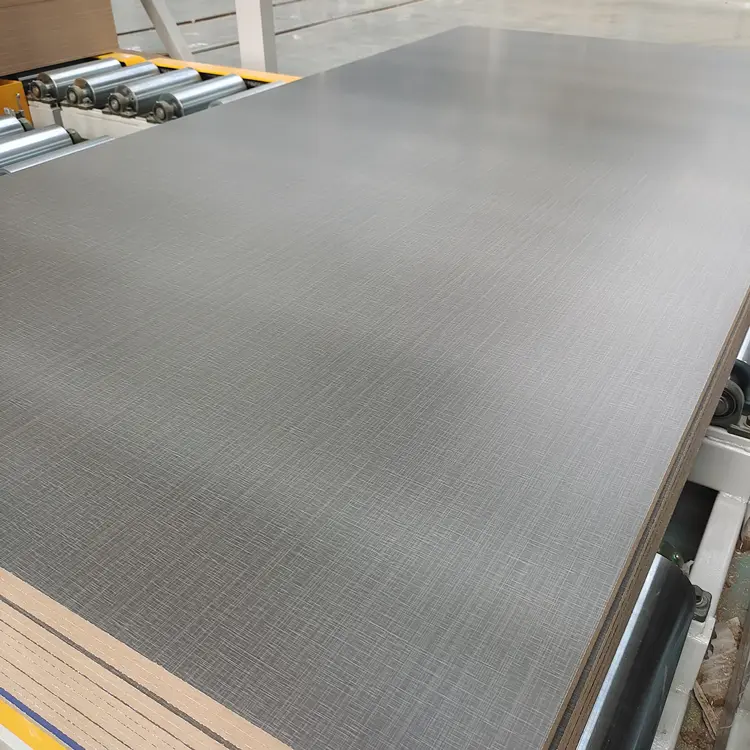

- Surface finish (e.g., raw, melamine MDF, primed).

- Supplier and location (e.g., India, Delhi, Chennai, Noida).

- Quantity purchased.

- Current Market price.

As a general rule, 8mm MDF offers excellent value for money, providing a good balance of performance and affordability. It’s often the most economical choice for projects where the strength of thicker boards isn’t required.

Where Can I Find High-Quality 8mm Laminated MDF Board?

Finding a reliable supplier is crucial for ensuring the quality and consistency of your MDF board. Look for manufacturers or distributors with a proven track record and relevant certifications (more on this later).

Many suppliers, especially in China, offer 8mm laminated MDF, which comes with a pre-applied decorative layer (usually melamine). This saves you the time and effort of laminating the board yourself. Demeter, for example, specializes in melamine faced board production, offering a wide range of colors and patterns to suit various design needs. Our production lines are top of the line, and we are a recognized leader in Delhi Sales Corporation. Factory wholesale cheap price High Quality 3mm 10mm 15mm 16mm 17mm 18mm melamine mdf board For Furniture cabinet door.

What are the Common Applications of 8mm MDF in Interior Design?

8mm MDF’s versatility makes it a popular choice for a wide range of interior design applications:

- Wall paneling: Creating decorative feature walls or wainscoting.

- Cabinetry: Used for cabinet doors, drawer fronts, and side panels.

- Shelving: Building lightweight and affordable shelves.

- Furniture components: Table tops, drawer bottoms, headboards.

- Shopfitting: Display units, counters, and partitions.

- DIY projects: Crafts, model making, and home improvements.

- Door skin: Used in the manufacturing of internal doors.

- Any craft which involves wood.

Its smooth surface is ideal for painting, allowing for a flawless finish. It can also be easily laminated or veneered to achieve different looks and textures.

What are the Advantages and Disadvantages of Using 8mm MDF?

Like any material, 8mm MDF has its pros and cons:

Advantages:

- Cost-effective: Generally cheaper than solid wood or plywood.

- Smooth finish: Provides an excellent surface for painting, laminating, and veneering.

- Consistent density: No knots or voids, making it easy to machine and work with.

- Dimensionally stable: Less prone to warping or twisting than solid wood.

- Easy to cut and shape: Can be cut with standard woodworking tools.

- Environmentally friendly: Often made from recycled wood fibers.

Disadvantages:

- Susceptible to moisture: Standard MDF can swell and warp if exposed to excessive moisture (although moisture-resistant options are available).

- Lower strength than solid wood: Not suitable for heavy load-bearing applications without reinforcement.

- Can release formaldehyde: Some MDF may contain urea-formaldehyde resins, which can release formaldehyde gas (look for low-emission or formaldehyde-free options). A potentially dangerous carcinogen.

- Edges can be difficult to finish: Requires careful sealing and finishing to prevent chipping or swelling.

How Does 8mm MDF Board Perform in Different Climates (Moisture Resistance)?

Standard MDF is not inherently waterproof. It will absorb moisture and swell if exposed to water or high humidity. This can lead to warping, delamination, and reduced structural integrity.

However, moisture-resistant MDF (often designated as MR MDF or HMR MDF) is specifically designed for use in humid environments. This type of MDF contains a higher percentage of water-repellent resins and additives, making it significantly more resistant to moisture damage.

If you’re using 8mm MDF in areas prone to moisture (e.g., bathrooms, kitchens, or basements), it’s highly recommended to choose moisture-resistant MDF. Even with moisture-resistant MDF, it’s still important to seal all edges and surfaces properly to prevent water ingress.

What Certifications Should I Look for When Buying 8mm MDF Board?

When sourcing MDF board, look for certifications that indicate quality, safety, and environmental responsibility. Some key certifications to consider include:

- CARB P2 (California Air Resources Board Phase 2): This certification sets strict limits on formaldehyde emissions from composite wood products, including MDF.

- E1/E0 (European Standards): These standards also classify formaldehyde emission levels, with E0 being the lowest (and safest).

- FSC (Forest Stewardship Council): This certification ensures that the wood fibers used in the MDF come from responsibly managed forests.

- ISO 9001: Quality management system. We use this system at Demeter.

These certifications provide assurance that the MDF board you’re buying meets certain quality and safety standards. They also demonstrate the supplier’s commitment to responsible manufacturing practices.

Can I Paint, Laminate, or Veneer 8mm MDF Board Easily?

Yes, one of the biggest advantages of MDF is its exceptional suitability for finishing. The smooth surface of 8mm MDF provides an excellent base for:

- Painting: MDF takes paint very well, producing a smooth, even finish. Use a primer specifically designed for MDF to seal the surface and prevent the paint from soaking in.

- Laminating: MDF is an ideal substrate for high-pressure laminates (HPL) and low-pressure laminates (LPL), such as melamine. The smooth, consistent surface ensures a strong and even bond. DEMETER Melamine wood MDF board 3mm 6mm 10mm 15mm 17mm 18mm manufacturer solid color white for furniture cabinet wardrobe

- Veneering: Thin sheets of real wood veneer can be easily applied to MDF to create the look of solid wood at a lower cost.

When finishing MDF, pay particular attention to the edges. They are more porous than the faces and require careful sealing to prevent moisture absorption and chipping. Use edge banding, wood filler, or multiple coats of primer/sealer to achieve a smooth, durable edge finish.

How to choose the right supplier, tips from the owner of an MDF factory.

Choosing the right supplier for your MDF and other decorative materials is critical for the success of your business. As Allen, the owner of Demeter, a wood-based panel and decorative materials factory in China, I can offer some insights based on my experience and what my clients, like Mark Thompson from the USA, look for.

1. Quality Inspection is Paramount:

- Surface Finish: Ensure the MDF has a consistently smooth surface, free from defects like scratches, dents, or uneven texture. For melamine-faced boards, check for uniform color and no delamination.

- Core Quality: Request samples and, if possible, cut them to inspect the core. It should be dense and uniform, without voids or inconsistencies. This affects the MDF’s strength and screw-holding ability.

- Color Consistency and Print Accuracy: If you’re buying melamine papers or printed papers, insist on consistent color matching across batches and accurate print reproduction. Good Quality melamine paper for plywood decorative melamine impregnated paper.

- Dimensional Accuracy: MDF boards should meet the specified thickness, length, and width tolerances. Inaccurate dimensions can cause major problems during manufacturing.

- Moisture testing, on request.

2. Certifications Matter:

Always ask for certifications like CARB P2, E1/E0 (for formaldehyde emissions), and FSC (for sustainable forestry). These aren’t just marketing terms; they represent real compliance with safety and environmental standards. These requirements are a must for a firm wishing to export to the USA and Europe.

3. Understand the Logistics:

Discuss shipping terms, lead times, and packaging thoroughly. Shipment delays can severely impact production schedules. Ensure the supplier has experience exporting to your country and can handle the necessary documentation. Demeter exports to North America, Australia, and Europe.

4. Payment Methods and Terms:

Negotiate clear payment terms that protect your interests. This might involve letters of credit, escrow services, or staged payments linked to quality inspections.

5. Communication is Key:

Efficient and clear communication is essential, especially when dealing with international suppliers. I’ve found that the biggest pain point for many buyers like Mark is poor communication. Ensure your sales representative is responsive, knowledgeable, and understands your needs.

6. Factory Visit (if possible):

If you’re planning large, regular orders, a factory visit can be invaluable. It allows you to assess the supplier’s capabilities, quality control processes, and overall professionalism firsthand. I often find that new partners who use Google search to source suppliers will use exhibiting at trade shows as an opportunity to find related categories near and find products similar to their requirements.

7. Price vs. Value:

While competitive pricing is important, don’t solely focus on the lowest price. Consider the overall value, including quality, reliability, and service. Sometimes, paying slightly more for a reputable supplier is a better long-term investment. Demeter understands that our clients’ profit model depends on reliable supply.

By addressing these points, you can establish a strong and mutually beneficial relationship with your MDF and decorative materials supplier, mitigating risks and ensuring a consistent supply of high-quality products for your business. As an architect, procurement officer, designer, or owner of a business that deals in wood and decorative products, you can depend on Demeter, send us an inquiry today. Our product gallery is available to view online, with company details and related categories available.

Key Takeaways:

- 8mm MDF board offers a balance of strength, workability, and affordability, making it suitable for various interior and furniture applications.

- While standard MDF is not waterproof, moisture-resistant options are available for humid environments.

- Look for certifications like CARB P2, E1/E0, and FSC to ensure quality, safety, and environmental responsibility.

- 8mm MDF provides an excellent surface for painting, laminating, and veneering.

- Careful edge finishing is essential to prevent moisture absorption and chipping.

- Choose a reputable supplier who prioritizes quality, communication, and reliable logistics.

- Demeter is here to fill all of your Medium Density Fibreboard requirements.

Post time: 03-12-2025