We’ve all been there. Standing in the lumber aisle, faced with a daunting mountain of wood options, each promising the perfect solution for your next DIY project. Plywood seems a touch too industrial, solid wood prices make your wallet weep, and then there’s the mysterious duo: MDF and chipboard.

Both are sheet materials, relatively affordable, and can be used for a variety of projects. But beneath the surface, MDF and chipboard are quite different beasts. Choosing the right one can mean the difference between a masterpiece and, well, a splintery mess.

So, how do you navigate this battle of the boards? Fear not, intrepid DIYer! This guide will be your trusty compass, dissecting the key differences between MDF and chipboard to help you select the champion for your next creation.

MDF: The Smooth Operator

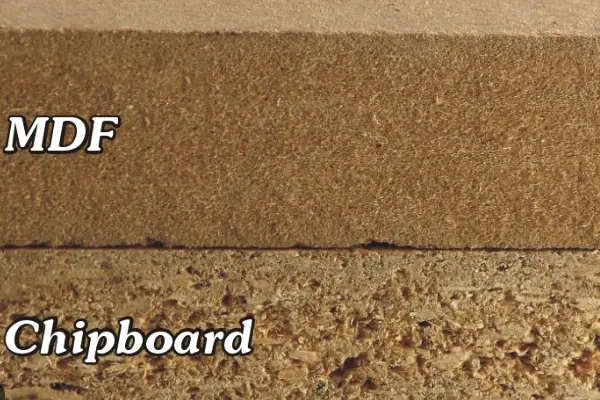

Imagine shredding wood into tiny fibers, blending them with a special resin binder, and then compressing them into a dense, flat panel. That’s the essence of MDF, or Medium-Density Fiberboard. The result? A remarkably smooth and uniform surface, perfect for projects where a flawless finish is desired.

Think clean lines, crisp paint jobs, and intricate cuts. MDF doesn’t have the visible wood grain of plywood, making it ideal for building shelves, cabinets, or even creating decorative signs. Its fine, uniform composition allows for precise cuts with minimal chipping or ragged edges, and its density makes it a great choice for applications where stability is key, like speaker boxes or furniture components.

Chipboard: The Rustic Charmer

Chipboard, on the other hand, takes a less refined approach. Imagine leftover wood scraps – shavings, flakes, and small chunks – bonded together with resin. The resulting panels have a rougher, more textured surface that reflects the inherent character of the woodchips used.

This rustic charm can be a desirable feature for some projects. Chipboard can be a budget-friendly option for furniture backs, substructures, or applications where the surface will be hidden from view. It’s also lighter than MDF, making it a potential choice for wall-mounted projects where weight might be a concern.

So, MDF or Chipboard? Let the Battle Commence!

Here’s a breakdown of the key factors to consider when choosing between MDF and chipboard:

Surface Finish: If a flawless, smooth finish is your goal, MDF reigns supreme. Chipboard’s textured surface is better suited for applications where a rustic look is desired.

Precision Cuts: MDF’s uniform density allows for clean and precise cuts, making it ideal for detailed projects. Chipboard’s uneven composition can lead to chipping or ragged edges during cutting.

Strength and Stability: MDF’s density makes it a stronger and more stable choice, especially for weight-bearing applications. Chipboard, while functional, can be less structurally sound.

Moisture Resistance: Both MDF and chipboard are susceptible to moisture damage. However, MDF tends to be even more sensitive to swelling and warping when exposed to water.

Weight: Chipboard is generally lighter than MDF, making it a potential advantage for wall-mounted projects.

Cost: Both MDF and chipboard are budget-friendly options, with chipboard typically being slightly cheaper.

The Final Verdict: It Depends on Your Project

There’s no clear winner in the MDF vs. chipboard battle. It all boils down to the specific needs of your project. For a sleek, painted finish with precise cuts and structural integrity, MDF is the way to go. If you’re looking for a rustic look, a hidden component, or a lightweight option, chipboard might be a suitable choice.

So, the next time you find yourself staring down the lumber aisle, remember this guide. Consider the surface finish, desired strength, and potential exposure to moisture to choose your champion. With the right knowledge, you can transform either MDF or chipboard into the building block for your next DIY masterpiece.

Post time: 06-07-2024